pressure bottle test|pressure testing for refrigeration : discounter High pressure cylinders are required to be hydrostatically tested every 5 years with the exception of composite and hoop wrapped cylinders manufactured prior to 2002 which are required to be tested every 3 years. All composite or . Resultado da instructions). • •! Internal Revenue Service

{plog:ftitle_list}

Resultado da OddsJet compares Coppa Italia odds from several reputable online .

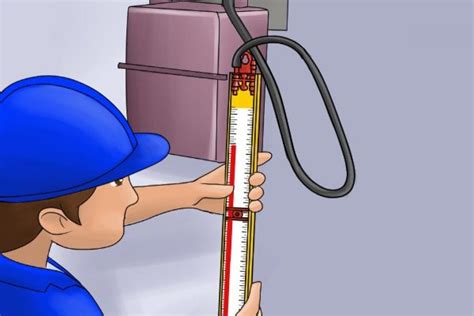

The test is called "Bottle Test"-- here is some info--. On the drivers side fuel rail-- to the back and next to the Turbo, you will see a "U". shaped 3/8 hose-- remove the hose from . The reason a Pressure Test is done is to ensure there are no leaks in the system before the vacuum is pulled, and the refrigerant is charged. In this article I will cover important .A hydrostatic test is a way in which pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the vessel or pipe system with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off th.High pressure cylinders are required to be hydrostatically tested every 5 years with the exception of composite and hoop wrapped cylinders manufactured prior to 2002 which are required to be tested every 3 years. All composite or .

The Model 350 is suitable for hydrostatic pressure testing on bottles, cylinders, and tanks with standard working pressures up to 15,000 psi (1,034 bar) according to military, nuclear, automotive, and aerospace specifications, such as API, .Hydrostatic Testing. The Compressed Gas Association (CGA) and the Department of Transportation (DOT) provide guidance on the safe transportation, storage, and use of high pressure oxygen cylinders. This includes the .The PPT3000 offers high-resolution, servo-controlled pressure and volume expansion testing for plastic and related containers. The system can be used to verify that containers meet minimum pressure capabilities and to monitor the .Hydrostatic testing is often required at certain intervals for aircraft oxygen cylinders, fire extinguishers and pneumatic bottles. The interval at which these are due and what is to be done is sometimes confusing.

Duramax LBZ LMM Fuel Pressure Relief Valve FPR return bottle test P0087. 0:00 /. Thanks to Kennedy Diesel for this nice writeup on how to do the bottle.

The process involves in-depth visual examinations of both the interior and exterior of the cylinder, along with a water pressure test or ultrasonic exam to confirm pressure-holding ability. All Safe Global is also proud to offer ultrasonic .To learn more about pressure decay leak testing, read our blog, Pressure Decay Leak Test: Why it is ideal for empty container leak testing. Empty Container Leak Testing Solutions from ALPS. The top 10 bottle blow molders .PTI offers over fourteen different tests for preform and bottle testing including burst pressure, density, dimensions, and more. X. This site uses cookies and by using the site you are consenting to this. We utilize cookies to optimize our brand’s web presence and website experience. . PTI offers over fourteen different tests for preform .CYLINDER HYDROSTATIC TESTING We perform visual inspection as well as government controlled (TC#047) and certified hydrostatic testing of cylinders of all sizes. We can also refill all SCUBA and SCBA cylinders with laboratory tested, clean, dry breathing air and CO2 cylinders with fresh carbon dioxide eliminating the need to make a second stop before getting back to .

custom elephant ear moisture meter

Pressure Testing, the right way. Regular pressure testing is essential to determining the integrity and performance attributes of PET bottles destined for pressure applications. Simulating real-world conditions is the only way to understand how bottles will perform under pressure during filling, in the warehouse and through retail channels.

Explore our superior pressure testing equipment with a testing range of -1/+6 Bar and pressure input of 4-6 Bar. Dimensions: 240x150x30mm. Net weight: 2.7kg.They are marked with graduated markings on the side to measure the volume of liquid within the pressure bottle accurately. Compare Tool. Select up to 3 products. Refine Results. Home All Products Media Bottles. 1 - 32 of 321. Sort . View . Show > Next; 1000mL Media Bottle, Square, PET, Bulk, Sterile .The PET Bottle Pressure (Burst) Tester is an advanced testing equipment for testing the PET bottles. It conforms to the three international common testing methods. Which are (1) Ramp Fill Mode; (2) Burst Mode; (3) User-Defined Mode. The machine uses a touch screen interface with automatic affusion, clamping the sample, and testing.Cylinders Testing Steps. Cylinders are tested using the water jacket method of testing cylinders that contain compressed air or gas. This method of testing cylinders essentially consists of enclosing the cylinder (filled with water), suspended in a jacket vessel and pressurizing the cylinder to a specific test pressure.

Part 1 in this series identifies the need for hydrostatic testing of self contained breathing apparatus used by firefighters and rescue personnel. Part 2 in this series will provide a summary of the frequency requirements and safety precautions associated with hydrostatic testing of self contained breathing apparatus compressed gas cylinders. Self-Contained Breathing .

A water rocket is a chamber, usually a 2 -liter soda bottle, partially filled with water. Air is forced inside the bottle with a pump. When the rocket is released, the pressurized air forces water out of the nozzle (pour spout). The bottle launches itself in the opposite direction. The bottle usuallyThanks to Kennedy Diesel for this nice writeup on how to do the bottle test:https://kennedydiesel.com/docs/Shim%20mod%20Bottle%20Test%20etc.pdf"the U shaped .GBBT-2 Glass Bottle Burst Tester for Dual Bottle Pressure Testing. View Device. Glass Bottle Burst Tester – GBBT-1. View Device. CEBT-1 – Can and End Buckle Tester .

Testing degas bottle cap 6.0 Powerstroke.Truck had coolant pressure issues:https://www.youtube.com/watch?v=mxXoro0Von4&feature=youtu.bepressure point (proof testing) or to destruction. In the event of destruction, the burst pressure is captured and stored. The dual station design allows operators to load one container while the second container is being testing. The Ramp Pressure Tester 2X (RPT2X) is an advanced testing instrument developed for pressure testing glass containers.

Traditional test methods in the field produce a go/no-go result that does not determine when, or if, the gas pressure inside the bottle has dropped to a critical level. Modern advances in magnetron technology have enabled .The test pressure shall be maintained for at least 10 minutes. It may then be reduced to the design pressure and conduct the examination for leakage. During the test, a pressure relief device shall be provided, having a set pressure .

The Ramp Pressure Tester 3 (RPT3) is the latest in a long history of advanced pressure testing instruments that combines Agr’s proven testing protocols with the latest technology. The RPT3 is designed to perform precisely to the rigid testing requirements of the glass container industry, and tests fully conform to ASTM C-147 and ISO 7458 . A manufacturing process “in control” will result in end-of-test pressure decay values that fall consistently in a predictable range around the average. In addition, the average value will not change appreciably over time when the process is “in control”. A single end-of-test pressure decay value is referred to as “x”.The cylinder pressure test gauge consists of a nickel-plated brass body that incorporates a bleed valve, operated by rotating a finger screw. The gauge mounted into the top of this body is a 350 bar gauge with a luminous face. The handwheel and liner enables the test gauge to be screwed into both 200 and 300 bar cylinder valves with an EN144-2 .

While not referring to hydrostatic testing by name, Part 180.205 addresses both the performance and the frequency requirements for “pressure testing” steel and aluminum SCBA cylinders. A hydrostatic test is commonly used for testing the SCBA cylinders because it meets all of the DOT’s pressure test performance requirements. This apparatus has a pressure gauge that measures the applied hydraulic pressure to the bottle interior in the range from 0 psi to 1000 psi. During fracture testing, the bottle pressure was increased slowly till failure. The failure pressure was noted and the bottle removed from the test rig and examined.Hydrostatic Testing. The Compressed Gas Association (CGA) and the Department of Transportation (DOT) provide guidance on the safe transportation, storage, and use of high pressure oxygen cylinders. This includes the hydrostatic test requirements on all cylinders. All cylinders are marked on the shoulder of the tank, to designate the type of .

The launch latch should be able to grab the bottle as soon as some pressure is added to the bottle rocket. You can test this by putting an empty bottle rocket on the launch tube, pushing it completely down, and then pulling it back up. The bottle should come up a tiny bit, until the release latch stops it. A couple of years ago O’Rileys had a coolant pressure test kit. 0 plus for two adapters in smaller, separate box. One of those extra ones fit my 2006 degas bottle. Wish I had noted the p/n but I didn’t. If you don’t want to keep it they return for 100% refund.

Video 1: Measuring the Pressure Inside a Soda Bottle 4 This protocol is simple enough that you can carry it out at home if you have an appropriate balance. 5 Even though the procedure it simple, it allows for a wide variety of explorations. For example, we determined P CO2 inside bottles of various sizes: 2L, 500 mL, and 355 mL. We found that sodas generally .PET Bottle Burst Tester PBBT-2: Accurate Pressure Testing for Safety and Quality. The PET Bottle Burst Tester PBBT-2 is designed to evaluate the expansion resistance and explosion risk of PET bottles, accurately simulating real-world filling conditions to ensure safety and quality.

custom false moisture meter readings drywall

pressure tightness test

No Quizur você pode criar seu quiz e criar seu teste de perso.

pressure bottle test|pressure testing for refrigeration